Energy Production and Infrastructure Center

To meet the workforce and technical research demands of the energy engineering industry in the Charlotte region, the North Carolina General Assembly established the Energy Production and Infrastructure Center (EPIC) at UNC Charlotte in 2008. As a collaborative, multidisciplinary endeavor, EPIC brought together the academic and research expertise of the university with the great wealth of energy engineering talent in Charlotte. EPIC educational programs at the undergraduate and graduate levels emphasized the application of engineering skills on energy challenges. Collaborative research areas included power distribution and grid management, intelligent management, manufacturing of large power generation equipment, renewable energy, and environmental impacts.

Lee College of Engineering Dean Bob Johnson developed the initial concept for EPIC. Through the urging of local energy and technology leaders such as Dhiaa Jamil of Duke Energy and Mark Boomgarden of Akoustis, Johnson proposed an academic and research program that would respond to the growing workforce demand for energy engineers and the need for alternative and more-efficient energy solutions. In 2007, Johnson wrote a whitepaper proposing EPIC. With the backing of industry representatives, he convinced UNC Charlotte’s upper administration that an energy engineering program was a good idea. The university proposed the program at the state level, and through the persuasion of additional energy professionals and soaring gasoline prices, convinced them that EPIC was needed. (For more information on the founding of EPIC see the chapter “Expanding 1998-2015.)

In 2008, the North Carolina General Assembly appropriated $76 million for the construction of the EPIC building and $5 million a year in recurring funds to hire 37 new faculty and staff in the area of energy engineering. The Energy Production and Infrastructure Center was born.

Steve Patterson of Mechanical Engineering was the first interim director of EPIC. Interviewed at the time, Patterson said an important part of EPIC’s mission was to educate the next generation of power plant engineers. “The type of power plants these engineers will be working in will be varied,” he said. “The plants will include traditional nuclear and fossil fuel, as well as emerging solar, wind, biofuels and other alternative energy forms. EPIC is very much about generational change in the energy industry. In one sense the generational change is in terms of ideas about new forms of power production. In another sense it’s about generational change in terms of people.”

Power engineering companies in Charlotte at the time included Shaw Group, Duke Energy, AREVA, EPRI, URS Washington Group, Westinghouse, Siemens, Metso Power, and Parsons. “EPIC will be very much about regional economic development, as we educate the engineering workforce to make these companies successful,” Patterson said. “The industry collaboration within EPIC is leading to the expansion of energy engineering studies in our classrooms. Part of what we’re doing is developing and implementing energy concentrations based on industry needs.”

Lighting Ceremony

On the extremely cold night of January 26, 2010, industry, university and state representatives marked the beginning of construction for the EPIC building with a lighting ceremony. The cold and windy night kept the speeches short, as UNC Charlotte Chancellor Philip Dubois, College of Engineering Dean Bob Johnson, and Duke Energy Group Executive and Chief Nuclear Officer Dhiaa Jamil gave the crowd of supporters an overview of the project. Following the speech making, they pushed a button that lighted the corners of the building site and a large balloon marking the center.

“The chill in the air reinforces a message,” Dubois said that night. “We depend on reliable and affordable energy. But there is a significant challenge inherent in our need for energy – people – the right people to provide that energy. We are answering the call for energy engineering talent and research through EPIC.”

The fall of 2010 was also historic for EPIC, as the first faculty members hired with the new state funding appropriation joined the Lee College of Engineering. The new faculty included Valentina Cecchi, Sukumar Kamalasadan, Miguel Pando, Matt Whelan and Brett Tempest.

Gifts

On January 24, 2011, Charlotte companies Duke Energy and Siemens Energy announced combined gifts of $8.8 million for EPIC. Duke Energy provided $4.5 million and Siemens Energy $4.3 million in support of scholarships, research facilities and faculty positions.

“The generous financial support from Duke Energy and Siemens are integral to the gathering momentum of the EPIC project,” UNC Charlotte Chancellor Dubois said at the announcement ceremony. “We at UNC Charlotte are most grateful for the ongoing support of these two energy leaders. This support reflects the depth of academic and industry collaboration in the Charlotte region. We also are grateful for the steadfast support of the State of North Carolina in its crucial funding to build the EPIC facility and to hire staff and faculty.”

The Siemens gift provided funding for undergraduate and graduate scholarships, support for a veterans’ outreach program, and support for a visiting scholars program to bring in key researchers from outside the U.S. to work with EPIC associates. Siemens also provided machinery time at its 550,000-square-foot plant southwest of Charlotte for faculty to work on advanced manufacturing concepts.

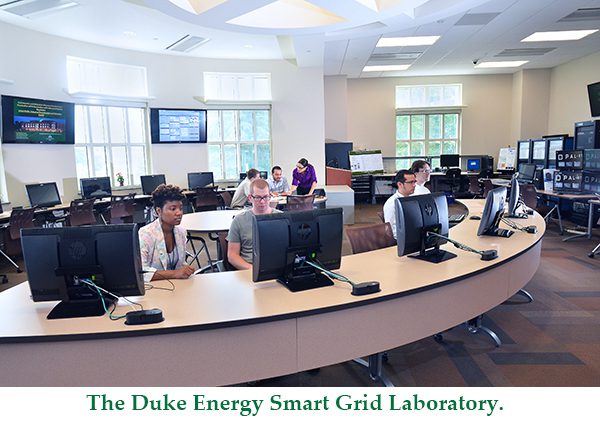

The Duke Energy gift funded a student fellows program, a distinguished professor position to help build the EPIC program, and the Duke Energy Smart Grid Laboratory to advance research in the area of grid modernization.

Another major gift came to EPIC on Dec. 12, 2011, when Westinghouse Electric announced its commitment of more than $3 million in donated equipment, services and scholarship funding. The donation included two 30-ton industrial cranes; training equipment for the handling of nuclear fuel; a training course for the design of fuel-handling equipment; training resources and facilities related to the nuclear generator plant operations and safety; and an introduction to a robotics-assisted welding manufacturing course, along with use of the Westinghouse welding training facility in Rock Hill, S.C.

Johan Enslin

As the first full-time director of EPIC, Johan Enslin came to UNC Charlotte in the summer of 2011 as the Duke Energy Distinguished Professor in Power Systems. He had worked the previous 12 years in industry, his last position being chief technology officer at the smart grid and renewable energy technology company Petra Solar in New Jersey. During his career, Enslin had always been involved with universities.

“I always had a passion for universities,” Enslin said, “having served on committees for graduate students and advisory board, and teaching classes as an adjunct at NC State. Coming to EPIC was a very appealing opportunity. I still had a lot of responsibility to work with industry, but also got to work with the next generation of workforce in this area and do applied research. It was a good match for my background.”

Some of Enslin’s first tasks at EPIC were to develop goals for the program and then make sure the new building would support those goals. “With input for our industrial partners, we developed strategic plans for academic programs, research program and economic development,” Enslin said. “The country was just recovering from a recession, so the power industry around Charlotte was looking to EPIC to provide economic development, workforce development, technology development, new IP opportunities and applied research. We then worked on the layout of the building and its labs, looking at what facilities were planned and then updated them based on the strategic plans for EPIC.”

New Building

In the summer of 2012, the collaborative nature of EPIC got a huge boost with the opening of its $76-million building on the UNC Charlotte campus. As the university’s largest academic building at 200,000 square feet, the new facility provided the classroom, office and laboratory space needed for the program’s growth.

“The new building brought together the multidisciplinary aspects of EPIC,” Enslin said. “Electrical, computer, mechanical, environmental and civil engineers came together to solve multidisciplinary problems. Students got involved in real-world projects that were sponsored by industrial partners.”

The new building was essential to the success of EPIC, Johnson said. “To make a research program go you had to have the right kind of laboratories for students to work in, which meant you had to have the right kind of building. The new facility provided these key elements.”

In addition to multidisciplinary lab facilities, the building was the new home of the departments of Electrical and Computer Engineering, and Civil and Environmental Engineering. Housed under one roof, undergraduate and graduate students from these disciplines now had the opportunity to study and collaborate with each other and with leaders in the energy field.

Classes began in the EPIC building in August of 2012. The official dedication of the building was November 16, 2012. Some of the outstanding laboratory features of the new building included:

- High Bay Structures Laboratory – with a 32-foot-tall, 1-million-pound-capacity strong wall, and a 92-foot by 47-foot strong floor, two 30-ton cranes donated by Westinghouse, networked 3-D shaker tables, high-impact sensing and 3-D laser-based optical tracking instrumentation.

- Duke Energy Smart Grid Laboratory – with a real-time data system simulator (RTDS), phasor measurement units and a host of simulation software packages and hardware equipment used to analyze and visualize system grid conditions for distribution and transmission networks.

- Environmental Laboratory – composed of a set of environmental laboratories designed to foster interdisciplinary collaboration amongst faculty and students in areas including environmental impact assessment, air quality monitoring, stream restoration, recreational water safety and wastewater treatment.

- Senior Design Laboratory – with computing resources and shared space designed to enhance collaborative design projects for student teams’ capstone senior projects.

- HP Energy Innovation Laboratory – for power systems analysis including unbalanced three-phase modeling of distribution system components and loads, distribution power flow techniques, and study of the impact of distributed and renewable energy resources on the distribution system.

- Duke Energy Power Suite – made up of the Power Distribution Systems Laboratory; Power, Energy and Intelligent Systems Laboratory; and the Electrical Machines, Drives and Protection Laboratory.

- AREVA Power Systems Teaching Laboratory – an interactive educational facility for experiments covering basic electromagnetic principles and the operation, control and protection of electrical power systems. Equipment included electromagnetic trainers, reconfigurable motors and generators, electronic motor drives, and systems to simulate protection of transmission lines, busbar systems, motors and generators.

- Siemens Large Manufacturing Laboratory – included a temperature controlled high-bay space with capability for handling large components. Major equipment included a large 5-axis machining center, a large coordinate measuring machine and laser trackers.

The EPIC building earned LEED-certified Gold status by implementing a number of advanced energy-saving technologies. LEED, or Leadership in Energy and Environmental Design, was an internationally recognized mark of excellence for implementing practical and measurable green building design, construction, operations and maintenance solutions.

Some highlights of the EPIC building that led to the LEED certification include:

- An active chilled beam HVAC system combined with outside air heat recovery units that reduced energy costs 20-25 percent.

- Daylight lighting from a central atrium, and numerous exterior and interior windows used in conjunction with light shelves to distribute light throughout the building.

- Exterior shading optimized to reject heat but allow lighting.

- Motion sensitive light sensors to turn off lights not in use.

- Zoning of space to make the best use of external light and heat.

- Interior water conservation from a gray water system and high condensate volume from the HVAC system.

- Rain gardens to trap and store water for irrigation.

Academics

The building was important to the success of EPIC, but equally so were the new faculty members who would develop and teach the energy academic programs.

“Without new faculty who could really make a contribution it would have been very difficult to get this program off the ground,” Enslin said. “We decided that first we had to build the programs and then the students would come. That was also very important. We looked at the existing energy courses and curriculum and made some changes to them to make them more relevant. We then developed energy concentrations around these courses and other new courses we created. Those energy concentrations provided opportunities for students to get scholarships, but also to focus their education on energy-related topics.”

EPIC educational programs at the undergraduate and graduate levels emphasized the application of engineering skills on energy challenges. Educational focus areas included the design, manufacturing, construction and maintenance of power generation, transmission and distribution systems; technical aspects of nuclear and environmental monitoring and maintenance; and sustainable engineering and multidisciplinary project engineering.

“Each of the different disciplines had an energy concentration at the undergraduate level,” Johnson said. “This meant all of their engineering technical electives were in energy-related subjects. Within our graduate programs students could also focus their studies on energy topics, and a new Master’s of Science in Applied Energy and Electro-Mechanical Systems was developed. The energy programs were all aimed at allowing students to hit the ground running in the energy field.”

Research

To quickly build strong energy research areas, EPIC hired teams of faculty who could collaborate together in specific areas. “I think it was important that we were able to make cluster hires,” Enslin said. “That really made a step change in the amount of the research activity and in the amount of output. It was a great decision led by our industry partners, the university and the state.”

The initial strategic research areas included power grid modernization, manufacturing issues associated with large power generation equipment, renewable energy generation including photovoltaics, wind, geothermal and biofuels, and environmental improvement associated with fossil fuels, power generation issues, and transmission and distribution systems.

As EPIC grew, new research areas that developed included coal fly ash stabilization and reuse, energy efficient buildings, energy efficiency in transportation, and energy storage for use with renewables.

To focus and concentrate the applied research of EPIC faculty members, students and industrial partners, EPIC organized five research clusters. These collaborative, multidisciplinary efforts were:

- Power systems modernization – composed of the Duke Energy Smart Grid Laboratory with RTDS and system analysis; distribution automation and micro-grids; electric vehicle and energy storage integration.

- Large energy component design and manufacturing – with the Siemens Large-scale Manufacturing Laboratory; Materials Characterization Laboratory (MCL); robotics and welding technologies.

- Renewables and energy efficiency – composed of a clean-room for PV cell and LED research; off-shore wind, biomass and small-scale hydro technologies; integration of renewables and energy efficiency measures.

- Power infrastructure and environmental development – with the large-structures laboratory and T&D designs; utilization and recycling of spent fuels and emission controls.

- Energy markets and systems engineering – for quality assurance, nuclear safety, regulatory and standards; distributed energy markets; and improved supply chain utilization.

Collaboration

With more than 240 regional energy corporations, Charlotte had become North American’s energy engineering hub. As a regional university center, EPIC was uniting and concentrating the strengths of these many companies. The input of the energy industry helped create EPIC, and as the center grew industry representatives continued to help refine and develop its research and academic programs. Formal EPIC industrial groups included an implementation team, advisory board and energy council.

“The implementation team of about 25 industry stakeholders helped to initially establish the program,” Enslin said. “They wrote the job descriptions for the positions we were hiring. That was very helpful in making sure the faculty we hired would work in areas of interest to our industrial partners.”

Beyond advisory roles, industrial partners also led seminars, created student internships, sponsored senior projects, collaborated on research, and hired many of the energy engineering students. Industry partners, faculty and students also joined forces to create startup companies such as SineWatts. The EPIC building also became the home of entrepreneurial and trade organizations such as E4 Carolinas and CLT Joules.

In its first seven years, EPIC successes included developing high-quality academic and research programs, building state-of-the-art laboratories, and providing industry partners with the workforce development and research program they needed. All of these successes combined to create a positive reputation for EPIC.

“Our focus was to really establish a good reputation locally, nationally and internationally,” Enslin said. “We held a few workshops and forums on subjects such as coal ash and smart grids. We also hosted a major IEEE conference and big manufacturing metrology conference, which helped put us on the map. We were getting the word out. We were also very proud of the direct industry funding we were getting, which meant we were focusing on the applied research that industry wanted.”