Materials Characterization Lab Offers Advanced Analytical Resources

Providing faculty and student researchers with advanced materials analyses resources, UNC Charlotte’s Materials Characterization Lab (MCL) offers sampling services, training, shared instrument usage and expertise at a convenient location and affordable cost.

A staffed analytical research facility, the MCL offers a range of thermal analysis and materials characterization instrumentation and services. The lab is in Cameron Hall on the UNC Charlotte campus, and is open to on- and off-campus researchers.

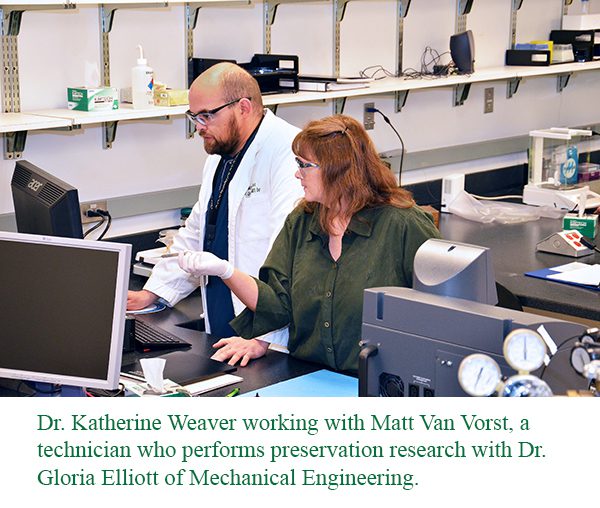

The MCL is under the direction of Dr. Katherine Weaver, whose specialization is analytical chemistry and materials science. Along with expertise gained through a Ph.D. in chemistry from Duke University, Dr. Weaver brings mechanical talents to operate, maintain, and take apart and reassemble almost all of the equipment in her lab.

“The MCL is our way to help grow research on campus,” Dr. Weaver said. “We can run a small sample for an individual project, or support a full thesis or dissertation research program. Right now we work with undergraduate and graduate students, and faculty from chemistry, biology, all of the engineering disciplines, and architecture.”

By providing shared resources, the lab gives researchers the option to do advanced analysis without having to purchase and maintain expensive equipment themselves, get samples processed when their department lab equipment is in use for other projects, and do proof-of-concept research needed for grant proposals.

“We now have a growing group of researchers using the lab,” Dr. Weaver said. “They are from our university and other campuses, and we have a number of industrial clients.”

A researcher who has used the MCL since its inception is Dr. Gloria Elliott of Mechanical Engineering and Engineering Science. “We currently use the DMA (Dynamic Mechanical Analyzer) to study sugar glasses that we use in our biopreservation research,” Dr. Elliott said. “The DMA helps us understand how the molecules and parts of molecules move, and how that impacts their ability to function as a storage medium.”

This type of analysis would not be economically feasible without the shared MCL facility, Dr. Elliott said. “The MCL is an incredibly valuable resource, especially with the escalating costs of maintaining and repairing analytical equipment. We wouldn’t be able to afford this type of analysis through a single research grant; we just couldn’t keep up with costs. This shared resource is fantastic.”

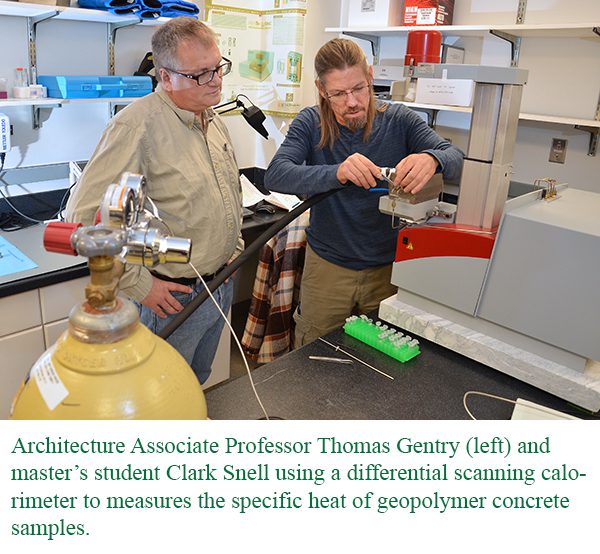

Another researcher who uses the lab is architecture masters student Clark Snell. “I’m working with the geopolymer concrete we used in the Solar Decathlon house,” Snell said. “I’m trying to quantify the thermal properties on a component level, so we can optimize these thermal properties and the thermal conductivity to create an optimum concrete mixture.”

Another researcher who uses the lab is architecture masters student Clark Snell. “I’m working with the geopolymer concrete we used in the Solar Decathlon house,” Snell said. “I’m trying to quantify the thermal properties on a component level, so we can optimize these thermal properties and the thermal conductivity to create an optimum concrete mixture.”

To perform this research, Dr. Weaver trained Snell to use a Sensys Evo differential scanning calorimeter. By heating samples and measuring the energy they absorb, the Sensys Evo measures the specific heat of the material.

“For me as an architecture student without an extensive chemistry background,” Snell said, “having Dr. Weaver to teach me how to do this work has been great. There’s really no way I could have done my thesis work on campus without this facility.”

The MCL is a charge-back unit, with varying rates based on the equipment being used. It does accepts industry research projects provided there is equipment time available, there is not an equivalent research service offered by a for-profit company at a lower rate, and the industry users agree to, and sign a services agreement covering confidentiality and intellectual property.

Materials Characterization Lab Analytical services and equipment include:

Thermal Analysis

Thermal analysis is a branch of material science where materials are characterized based on the changes in their properties as a response to temperature. The methods available are distinguished with respect to the property being measured. The MCL’s thermal analyses capabilities include:

Thermal analysis is a branch of material science where materials are characterized based on the changes in their properties as a response to temperature. The methods available are distinguished with respect to the property being measured. The MCL’s thermal analyses capabilities include:

- Dynamic Mechanical Analysis (DMA), a technique used to measure the mechanical stiffness and damping properties of a wide range of materials.

- Thermogravimetric Analysis (TGA), a technique used to measure the changes in weight of a sample during a controlled temperature program.

- Combined Thermogravimetric-Differential Scanning Calorimetry (TG-DSC), also known as Simultaneous Thermal Analysis (STA), is a technique used to simultaneously measure changes in mass (TGA) and changes in heat flow (DSC) on one and the same sample in a single instrument running a controlled temperature program.

- Thermal Conductivity (TCi), an analysis that provides a non-destructive method to measure both effusivity and thermal conductivity of fluids, pastes, solids and powders.

Rheology

Rheology is the study of the viscoelastic properties of liquids and soft solids that flow rather than deform elastically. MCL rheology equipment and services include a Rotational Rheometer used for determining the flow characteristics for fluids of any viscosity and polymer melts. Rheology is often used to establish the relationship between deformation (strain) and force (stress) imposed during the production of polymeric materials and other industrially important substances such as food and pharmaceuticals.

Rheology is the study of the viscoelastic properties of liquids and soft solids that flow rather than deform elastically. MCL rheology equipment and services include a Rotational Rheometer used for determining the flow characteristics for fluids of any viscosity and polymer melts. Rheology is often used to establish the relationship between deformation (strain) and force (stress) imposed during the production of polymeric materials and other industrially important substances such as food and pharmaceuticals.

Microcalorimetry (Nano-ITC)

Calorimetric analyses accurately measure the rate of heat absorbed or evolved when a molecule of interest interacts with another molecule. Nano-Isothermal Titration Calorimetry (Nano-ITC) is used for binding and kinetic studies of either dilute aqueous or organic based solutions. Substrate kinetic and ligand binding studies further the understanding of the macromolecular interactions important in many solution based applications.

Universal Testing Machines (Dual Column)

These machines test a range of materials in tension, compression, flexure, shear and peel modes, and are used to predict how a material will perform under these types of forces. Textiles (fibers, yarns, fabrics), paper and other products can be run on the the MCL’s 10 kN Universal Testing Machine. Applications include design testing in biomedical research, construction and consumer products.

Current Equipment

Current Equipment

- TA Instruments Q800 Dynamic Mechanical Analyzer TA Instruments AR2000ex Rotational Rheometer

- TA Instruments Low Volume Nano-Isothermal Titration Calorimeter

- TA Instruments Q500 Thermogravimetric Analyzer

- Setaram Instrumentation Sensys evo Calvet Thermogravimetric Analyzer/Differential Scanning Calorimeter

- TA Instruments Q600 SDT Differential Scanning Calorimeter/Thermogravimetric Analyzer

- C-Therm TCi Plane Surface Thermal Conductivity Analyzer

- Tinius Olsen H10KT Dual Column Load Testing Frame

- Evolved gas testing following TG-DSC analysis using FTIR or GC-MS is possible, but is not fully incorporated at this time.

Other Facilities

The MCL promotes interdisciplinary collaboration across departmental boundaries, and supports research strengths across the physical, biological and engineering sciences. Current researchers include architects, chemists, civil engineers, mechanical engineers and bioengineers. Access to instrumentation not included here can be arranged if availability permits. Please contact the MCL manager to learn more about additional testing options.

Contact

Contact

Internal student users should consult with their advisor prior to contacting the MCL for analytical needs. Your advisor should be aware of your interest in using the services provided in this lab.

External users from industry or other academic institutions are welcome to contact the MCL manager to inquire about arranging for testing services or setting up a project.

Dr. Katherine Weaver, Materials Characterization Laboratory Manager

704-687-0299